Why Do Motorcycle Brake Pads Have Grooves?

Motorcycle brake pads are critical components that ensure safety and performance on the road. At Yongli, a leader in high-quality brake pad manufacturing, we prioritize every detail to deliver the best braking experience. One such detail is the incorporation of grooves into our brake pads—a design feature that plays a vital role in enhancing braking efficiency and safety.

1. Debris and Dust Removal

During braking, friction between the brake pad and rotor generates dust and debris. If not managed properly, this buildup can interfere with the pad's ability to maintain consistent contact with the rotor, reducing braking performance. Grooves in the brake pads act as channels that guide dust and debris away from the contact surface, ensuring that the braking system operates smoothly and efficiently.

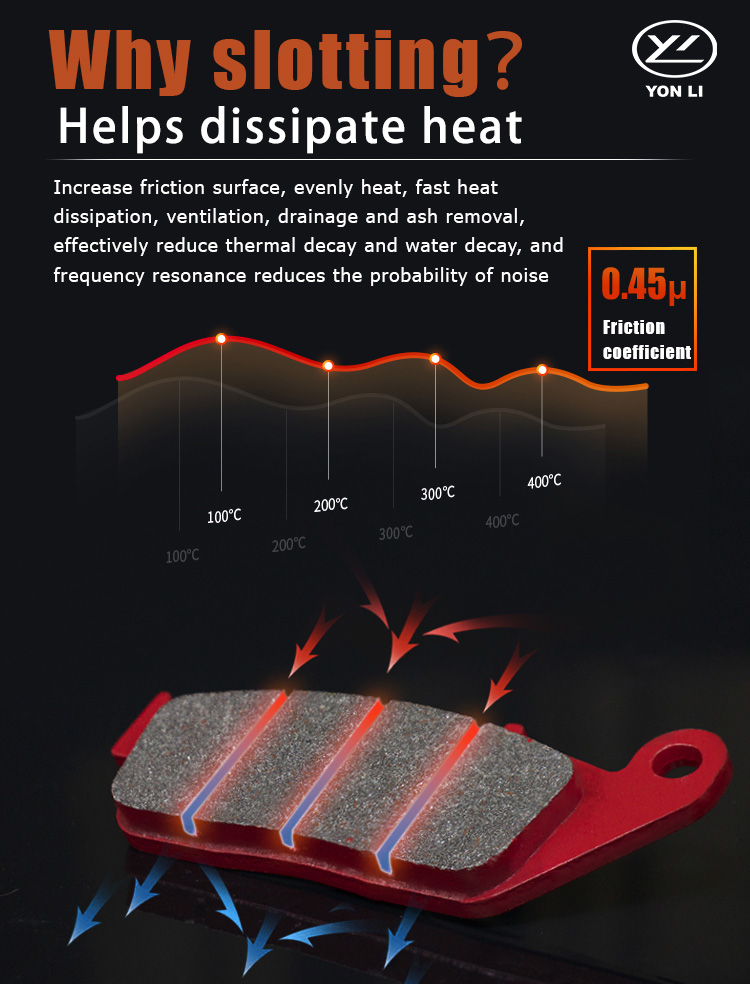

2. Heat Dissipation

Braking generates substantial heat, especially under high-stress conditions such as aggressive riding or repeated braking. Excessive heat can lead to brake fade—a condition where the braking power is reduced due to overheated components. Grooves in the brake pads enhance airflow around the pad and rotor, facilitating faster heat dissipation. This helps maintain optimal braking performance and prolongs the lifespan of both the brake pads and the rotors.

3. Water and Moisture Management

In wet or rainy conditions, water can accumulate between the brake pad and the rotor, creating a thin layer that can reduce friction and impair braking efficiency. The grooves in the brake pads serve as pathways for water to escape, preventing the formation of a water film and ensuring reliable braking performance even in challenging weather conditions.

4. Enhanced Friction and Contact

Grooves are not just for debris removal and heat management—they also play a role in improving the friction between the brake pad and the rotor. By creating additional edges and surfaces, the grooves increase the overall friction area, providing stronger and more consistent braking power. This is especially important for high-performance motorcycles that demand precise and responsive braking.

5. Reduced Brake Fade

Brake fade is a phenomenon where the braking system loses efficiency after prolonged use due to excessive heat. Grooves help mitigate this risk by promoting better heat dissipation and maintaining a cleaner contact surface between the brake pad and rotor. This ensures that the brakes remain effective even during extended periods of use, providing riders with the confidence they need in demanding situations.

Conclusion

At Yongli, our commitment to quality and safety drives every aspect of our brake pad design. The inclusion of grooves in our motorcycle brake pads is a testament to our dedication to providing products that deliver superior performance under all conditions. Whether you're navigating city streets or tackling winding mountain roads, you can trust Yongli brake pads to offer the reliability and safety you need.