What Are Sintered Brake Pads?

Friction coefficient: 0.52μ Heat temperature resistance: 600℃

Environmentally friendly heavy metal-free formula passed RoHS test and complies with EU regulations Sintered under high temperature and high pressure in a protective atmosphere to maintain good braking force in extremely high temperature riding environment Provide excellent control experience for motorcycle enthusiasts.

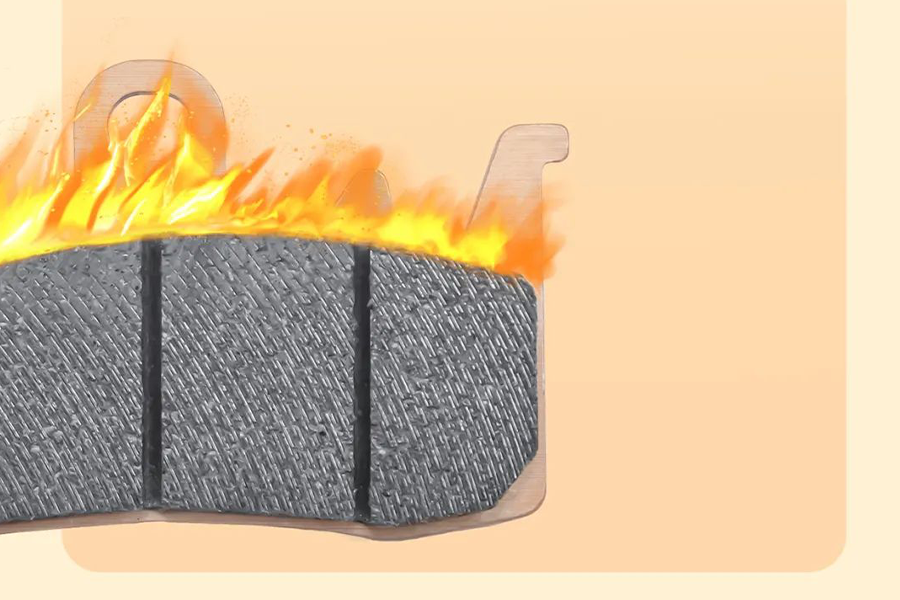

Resistant to thermal decay and more resistant to high temperatures

The unique regular stripes on the friction surface are the result of melting the metal during the sintering process, connecting the metals to each other, and the mutual catalytic crystallization of the material molecular structure, which creates the excellent temperature resistance and wear resistance of the sintered brake pads, and is not afraid of the braking temperature of up to 600°C.

Strong braking force

Yongli metal "sintered" brake pads have a friction coefficient of 0.52μ and are resistant to high temperatures of 600°C. They are suitable for off-road vehicles, modified vehicles, ADVs and other models with a displacement of more than 500CC. Their good thermal stability and braking performance can provide strong assistance and safety for riding.

Stable performance, safe and reliable

After sintering, the friction material will be firmly bonded to the steel backing. Even if it encounters severe impact, it will not deform or peel off. The textured bronze-colored skin-like surface is rich in micro pores, which can achieve rapid heat dissipation and maintain stable performance.

Click the link 【https://www.youtube.com/watch?v=5hxnyGIHoIM】to view the introduction of sintered series brake pads